NEWS

Why is the strength of steel used in China so high?

07-15

The strength of steel used here specifically refers to the amount of steel used per unit of gross domestic product (GDP). There are many reasons for China's high steel strength, but it largely reflects China's national conditions and development path chosen.

National conditions and development paths are formed over a long period of time and are not easy to change in the short term. The regulation of steel production capacity cannot be divorced from China's national conditions. In the face of the compensatory acceleration of China's economic growth this year, relevant parties announced a few months ago that China's steel production this year would decline year-on-year, which increased the market's expectations for steel prices. Only with a clear and objective understanding of the strength of steel used in China can we avoid or reduce the market fluctuations caused by misjudgments in the future.

Economic structure and development driving force determine the strength of steel

According to the definition of economists, China is a transitional economy that is increasing the proportion of marketization. In order to overcome the inherent shortcomings of the original planned economy, by seeking development through exploration, China's economy has blazed a unique development path in the process of catching up with developed countries.

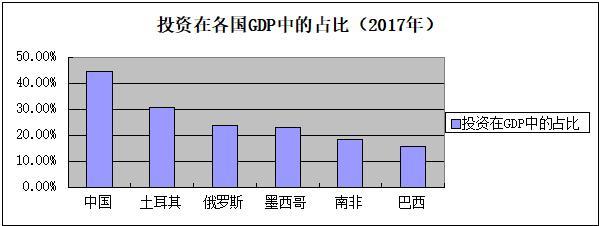

Compared with countries whose economies are at a similar stage of development, China's investment in the three major components of GDP is significantly higher. In the process of economic development, China has made infrastructure development ahead of schedule by increasing its investment in infrastructure. This is one of the main reasons for the high strength of steel used in China's economy.

Data source: WORLD FACT BOOK, CIA

The chart below compares the consumption of steel in China and the other five countries in the world. From the perspective of per capita GDP, these countries are at a similar stage of economic development as China. China's per capita GDP in 2019 is approximately equivalent to 10,216 U.S. dollars. In the same year, the per capita GDP of the five countries was between US$6001 (South Africa) and US$11,584 (Russia). Other countries participating in the comparison include Brazil, Turkey, and Mexico.